5 ½” vs. 5” Drill String Comparison for Unconventional Drilling

Share:

Challenge

Over the past several years, Workstrings Engineering department has received several requests from operators to prove the benefits of using 5 ½” drill pipe in comparison to 5” drill pipe, particularly for drilling lateral hole sections in horizontal and ERD wells. As the lateral lengths increase in unconventional drilling, this has become a more prominent option. Though every well and hole section are unique with specific operational challenges that must be met by the operator, operational benefits have been modeled and then proven, especially for 8 ½” and 8 ¾” hole sections, when operators chose to change their drill string to 5 ½” from 5”.

Benefits

Improved Hydraulics

One benefit when switching to 5 ½” DP from 5” DP is with regards to the improvement in hydraulics. The larger internal diameter of the 5 ½” DP results in a larger pipe flow area thereby decreasing the string pressure loss and reducing the required pump pressure. If required pump pressure is a limiting factor for the operator, switching to 5 ½” DP will allow for greater hydraulic design flexibility.

The larger OD of the 5 ½” pipe will also result in a smaller annular clearance thereby increasing annular velocity and helping to improve cuttings transport and hole cleaning. The smaller annular clearance will conversely increase annular pressure loss and downhole ECD, however it has been seen this increase in annulus pressure loss is much smaller relative to the decrease in string pressure loss, and the increase in downhole ECD was seen to be heavily dependent on rheology and hole size.

An example of the hydraulic benefits when switching to 5 ½” DP from 5” DP is shown below in Table 1, taken from a 20,000 ft. horizontal well while drilling an 8 ½” hole section TD.

| Pump Pressure (psi) | String Hydraulic Loss (psi) |

Open Hole Annular Velocity (ft/s) |

Annular Pressure Loss (psi) | Downhole ECD (ppg) | |

| 5” DP | 5611.13 | 4314.19 | 6.44 | 863.01 | 11.2 |

| 5 ½” DP | 4726.58 | 3092.45 | 7.25 | 1200.19 | 11.9 |

Table 1 - 5 ½” vs. 5” DP Hydraulic Comparison Table

IncreasedTorsional Capacity

The 5 ½” pipe will have greater torsional capacity allowing for longer wells to be drilled and decreasing the chance of connection damage or twist offs. A standard 5” NC50 drill pipe will have a maximum make up torque (MUT) capacity of 30,000 ft-lbs at 1.0 FF dope, while a 5 ½” drill pipe can have a maximum MUT capacity ranging from 46,300 ft-lbs to 59,200 ft-lbs at 1.0 FF dope.

Increased Stiffness

With high compressional forces being especially common while drilling and tripping in the lateral section of ERD wells, having the larger OD 5 ½” pipe will provide increased stiffness and help to mitigate the degree of buckling.

Increased Tensile Capacity

With all else being equal regarding the pipe grade and properties, the standard 0.361” wall thickness 5 ½” pipe will provide a higher tensile capacity compared to the standard 0.362” wall thickness 5” drill pipe as shown in Table 2 due to the larger cross-sectional area of the pipe, allowing for a larger margin of overpull and less risk of tensile failure.

| Wall Thickness (in) | Remaining RBW (%) | Grade | Tensile Strength (lbs) | |

| 5” DP | 0.362 | 80 | S-135 | 560,763 |

| 5 ½” DP | 0.361 | 80 | S-135 | 620,604 |

Table 2 - 5 ½” vs. 5” DP Tensile Strength Comparison Table

Heavier Pipe

The heavier 5 ½” pipe will allow for a greater downhole WOB transfer, giving the operator greater flexible when choosing drilling parameters.

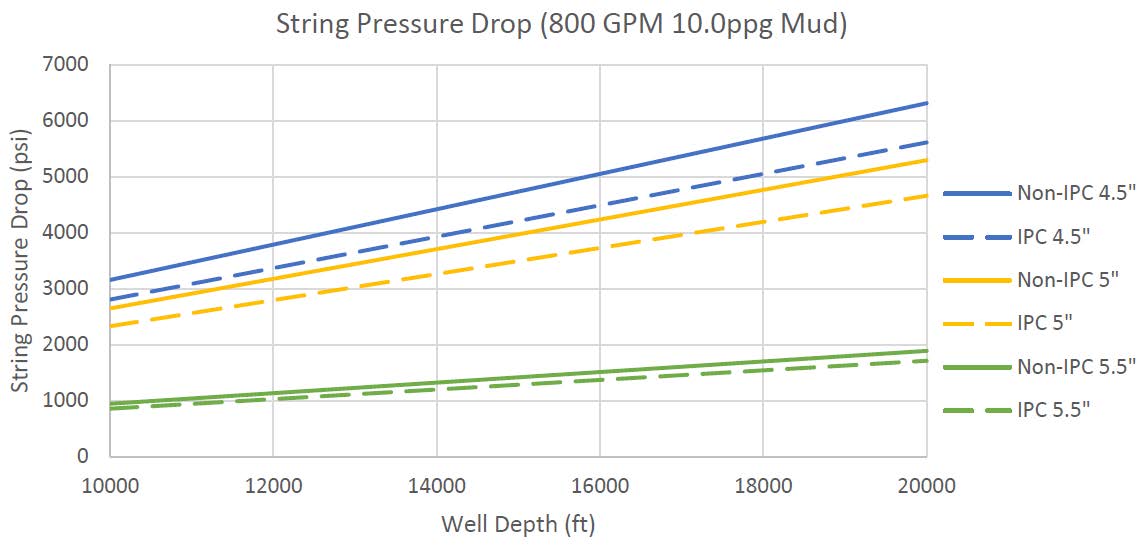

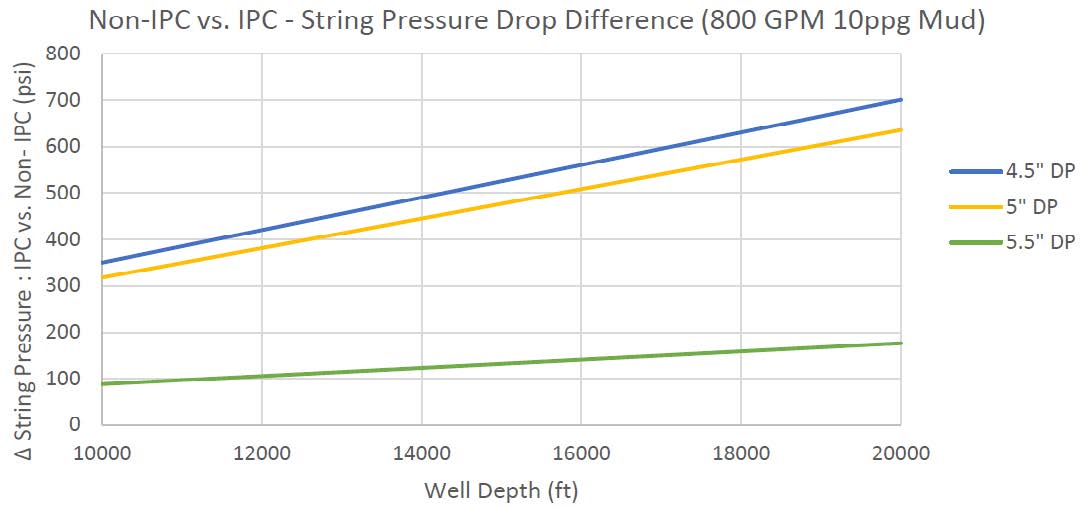

IPC vs. Non-IPC String Pressure Drop

Another hydraulic benefit is seen when using pipe with IPC (internal plastic coating). IPC results in a lower pipe roughness, causing a decrease in string pressure loss relative to identical non-IPC pipe. For a 15,000 ft. well at a flow rate of 800 GPM using 5” drill pipe, IPC pipe in place of non-IPC pipe resulted in a decrease in string pressure loss of 476 psi. For a 5.5” drill pipe in the same scenario, the decrease in string pressure loss was 132 psi. There is a more distinct difference with 5” and smaller pipe as shown below in Figure 1 and Figure 2.

Results

Across the US, operators in unconventional basins are beginning to see improvements in drilling performance as a result of the decision to switch to 5 ½” DP from 5” DP. By proving the benefits through modeling, then implementing the changes in the field, operators have been able to drill faster with higher WOB and higher flow rates while decreasing the likelihood of drilling operations being limited by drill pipe torque capacity, pump pressure, and buckling.

Let’s Tackle Your Biggest Challenges

From rental tubulars to custom-engineered solutions, Workstrings redefines limitations to help you secure success in your land, offshore, or deepwater projects. Let’s discuss your needs.