Specialty Drilling Tool Design

Workstrings® can help with a custom solution to maximize performance and profitability. Our engineering team can design specialty tools to address unique challenges and provide innovative solutions. Every Challenge is Unique. Unique is our Specialty.

A Tailored Approach to Success

With over 25 years of deep engineering capabilities, we continuously develop and perfect specialty work string tools and accessories to meet unique challenges and high expectations. We strive to help our customers execute their drilling, completions, and intervention programs successfully and efficiently.

WorkTech™ Joints

WorkTech™ Joints are specialty slick tubulars designed to be run through elastomers and sealing elements without causing damage, allowing for seamless movement through the closed annular BOP, including during frac operations to manipulate a frac tool or other components within the string. These are used for managed pressure drilling (MPD) operations through the rotating head to prevent elastomer wear.

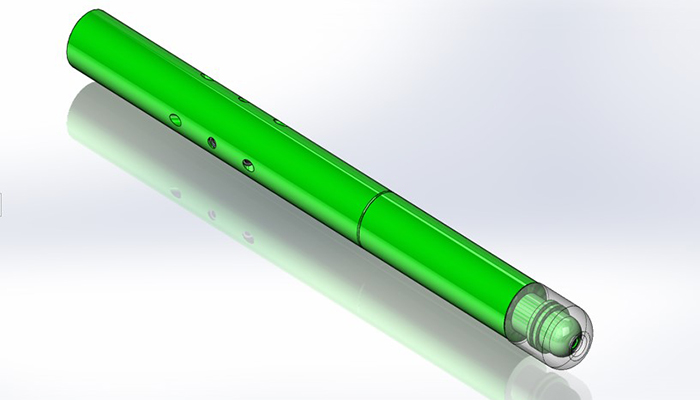

JetString™ Sub

Our patented JetString™ Subs are an enhanced jetting sub-assembly offering directional jetting and configuration flexibility that can be adjusted on location to match operational needs. It can be run in a drill string or in conjunction with our Bullnose Sub, which can also have the nose nozzle optimized or blocked off for flexibility while cleaning.

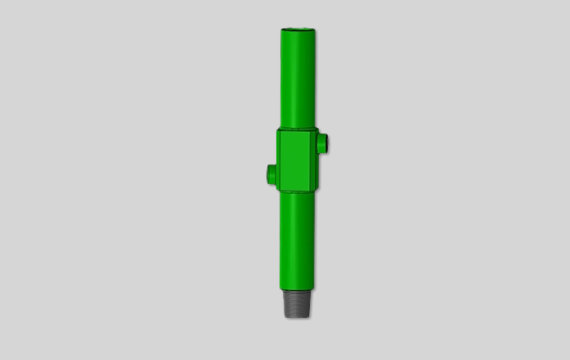

Side Entry Pump-in Sub (SEPI)

It’s critical that your SEPI sub has the tensile capacity to support the weight of the full workstring. Our in-house finite element analysis (FEA) ensures that our subs meet your design criteria.

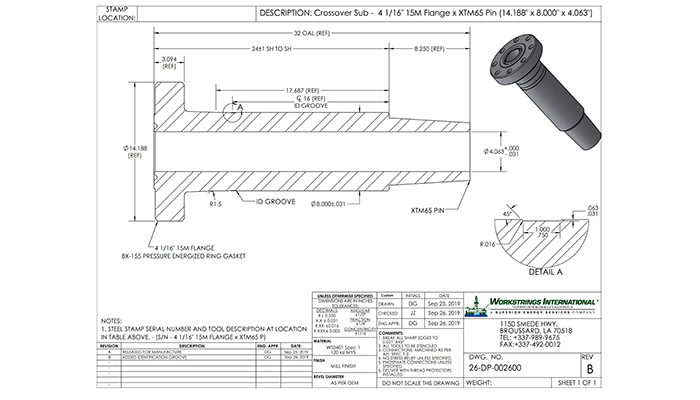

Custom Crossovers

Our custom crossovers are tailored to specific requirements to provide seamless integrity of the entire drilling assembly. We can design them to mate with casing, flanges and other drill string components to meet your needs.

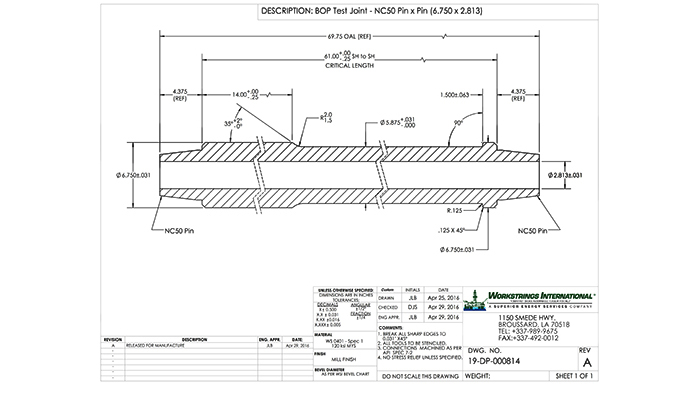

Custom BOP Test Joints

Workstrings can also custom engineer and build BOP-specific test joints designed to eliminate multiple trips to test BOPs, saving time and money.

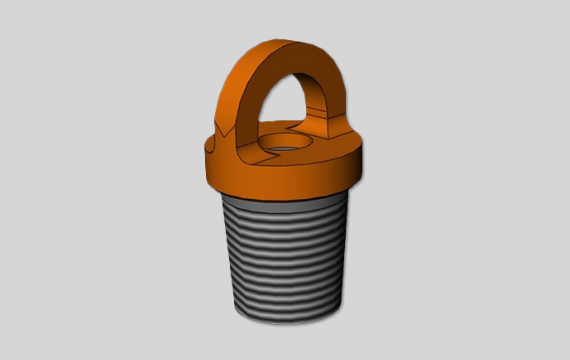

Integral Bleeder Plug Design

One-piece, integral bleeder plug customizable with hoisting ability.

Integral Lift Caps

One-piece, solid lift cap pull-tested and rated in-house to increase safety in lifting operations.

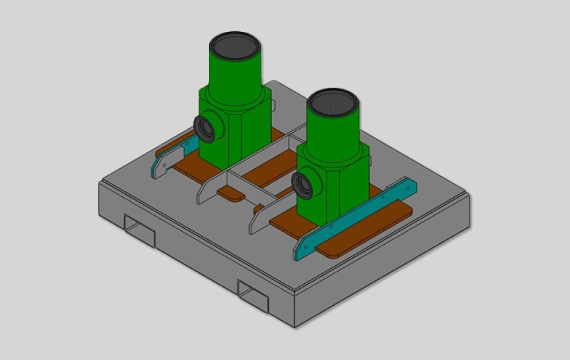

Integral Test Stump Stand

A convenient and reliable method for safely testing lower Kelly valves and equipment on location, saving valuable time.

Lift Sub with Side Outlet

An efficient side-entry design featuring a convenient lifting shoulder.

Real Results, Real Feedback

“Our team has been working on a new system to capture and dispose of proppant and fluids. Although Workstrings’ role was only a part of the overall solution, they provided us with the specialized discharge equipment and services we needed to avoid the costly process of proppant capture. We’re grateful for their support and expertise in helping us bring this concept to life.”

Specialty Drilling Tools, Complete with Custom Services

With a presence in 90 countries, Workstrings has seen and solved it all. For custom tools and comprehensive support, let’s talk.