Engineering Solutions, Backed by Technology

Over the past 25 years, we have developed a range of programs and software, reinforcing our technical support to help ensure safety, efficiency, and performance in 90 countries.

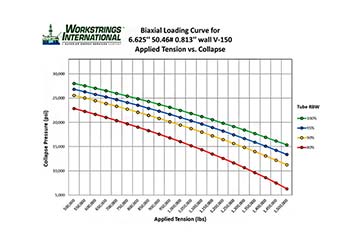

Biaxial Loading Analyzer

For BOP testing operations, our Biaxial Loading Analyzer calculates the reduced collapse of a tubular subjected to a tensile load.

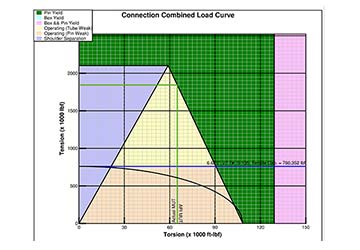

Connection Analyzer®

The Connection Analyzer® is used to evaluate the connection's capacity to carry combined torsional and tensile loads.

Connection Analyzer® is a Registered Trademark of TH Hill and Associates, A Bureau Veritas company.

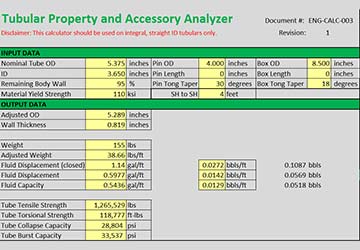

Tubular Property and Accessory Analyzer

Essential for determining pipe properties and component integrity of integral crossover subs and pup joints, our Tubular Property and Accessory Analyzer evaluates tensile, burst and collapse.

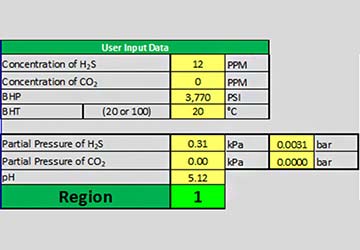

Sour Service Region Analyzer

Our Sour Service Region Analyzer calculates the NACE region using expected well parameters to help determine the tubular grade and corrosion mitigation requirements for a drill string or completion string.

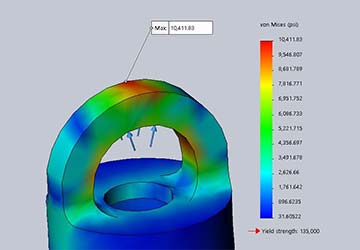

Finite Element Analysis (FEA)

Our FEA software can identify and address potential weaknesses and inefficiencies in tubulars or tool designs before they negatively affect operations by evaluating how they behave under different load and stress scenarios.

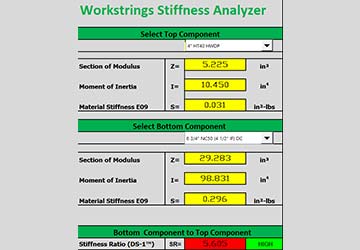

Stiffness Analyzer

Essential for ensuring a gradual transition between two components in the bottom hole assembly (BHA), our Stiffness Analyzer measures the ratio of stiffness to a less flexible component. It is used to ensure that the transition between two components in the BHA is gradual.

Effective Drilling Solutions Begin with Downhole Technical Support

In 90 countries for 25 years, Workstings® has been there and done it. For experienced tubular technical support, let's talk.