Innovation

Today’s Innovations, Tomorrow’s Standards

As a pioneer in downhole tubular innovation, we continually raise the bar for performance, safety, and efficiency. Collaborating closely with our customers, we directly confront their biggest and most complex challenges to deliver meaningful breakthroughs.

-

1995

5 ½” Drill Pipe in the Gulf of Mexico

Delivery of first 5 ½” drill pipe for deep water Gulf of Mexico.

-

1999

Dedicated landing string

5 ½” HT® 55 .750” wt landing string, the first designated landing string for deep water projects.

-

1999

XT-M™ Drill Pipe

SST takes delivery of the world's first XT-M™ (metal-to-metal seal TJ) completion pipe used to drill and complete the Gulf of Mexico extended reach well program.

-

2000

4” Drill Pipe in the Gulf of Mexico

4” HT™ 40 drill pipe was the first 4” drill pipe used in the Gulf of Mexico.

-

2000

5 7/8” for Deepwater Gulf of Mexico Drilling

The first 5 7/8” XT™ 57 drill pipe used in the Gulf of Mexico for deep water extended reach well project.

-

2002

4” XT™ 39 string

Groundbreaking design reducing equipment wear and improving performance in complex, high-torque applications—now used globally instead of 3 1/2” drill pipe.

-

2003

6 5/8” GT-M™ 69 Completion Landing String

Featuring a large inner diameter (5.250”) used to land tubing and provide a larger inner diameter for the drifting of crown plugs.

-

2004

5 7/8: CT-M™ 57 Completion Drill Pipe

Innovation for deep water completions introduced a new dimension in drill-pipe and landing-string technology, now the industry standard.

-

2004

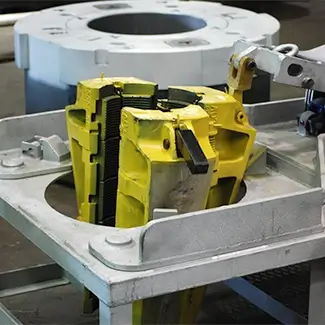

FASTR™ Handling System and 2MM LB Landing String

The first slip-based 2MM lbs. Landing String System & FASTR V-150 Landing String - The first 2 MM lbs. Landing string, 2MM lbs. Hydraulic Slip System, & 2MM lbs. Elevators.

-

2009

2.5-million-lb. Landing String

6 5/8”FH FASTR UD-165 Landing String - 2.5 MM lbs. Landing String (first UD-165 grade). This technology allowed deep water drilling deeper in the Gulf of Mexico by supporting extended strings of casing.

-

2010

6 5/8” GT-M™ 69 Completion Landing String

Featuring a larger ID (5.500”), used in landing tubing strings, providing a larger inner diameter used for drifting larger crown plugs.

-

2010

4” CT-M™ 39 & 2 7/8” CT-M™ 26 (25,000 PSI)

Designed for deep-gas completions, supporting a 28,789-ft flowline cleanout in the Gulf of Mexico.

-

2010

2 3/8” MW™ 20

The world's smallest specialty-designed drill pipe for high temperature, high pressure deep gas completions.

-

2011

6 5/8” TT-M™ 710 Completion Landing String

Featuring a larger ID (5.625”), used in landing tubing strings, providing a larger inner diameter used for drifting larger crown plugs.

-

2016

7 5/8” MaXit™ 807 Completion Landing String – Largest ID (6.250”)

Features the largest ID (6.250”), a major leap in vessel completion technology, improving tensile strength and fatigue resistance, ideal for complex, high-pressure deep water applications.

-

2016

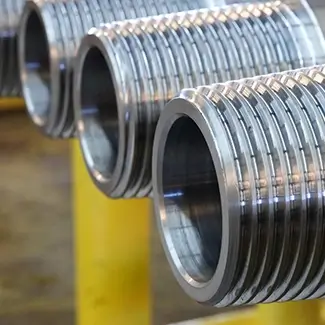

Proven Corrosion Prevention Coating

The world’s first anti-corrosion coating, significantly extending drill-pipe life, reducing maintenance costs, improving reliability, and enhancing operational safety.

-

2021

3-million-lb. Rated Landing String System

This industry milestone set a new benchmark for load-bearing capacity in high-pressure environments, reducing risks and downtime while boosting well construction efficiency.

Prioritizing Sustainable Innovations

Your operational success requires more than equipment. With 20 strategic locations in 14 countries, we can reduce your lead time, navigating customs, shipping routes, unique market and local compliance issues, and other challenges.

Committed to reducing our environmental footprint through innovation, we maintain transparency and environmentally responsible and compliant practices.

Proven External Coating and Carbon Reduction

By substantially reducing corrosion, innovations like our proven external coating significantly extend the lifespan of drill pipe and other tubulars, leading to fewer replacements and less waste. Less maintenance also means reduced downtime and emissions associated with repair.

Your First Step to the Next Big Thing

Workstrings is your one-stop global solutions provider for comprehensive oilfield services. Let’s discuss your challenges, your goals, your future.